The marine industry requires durable and reliable materials to withstand the harsh conditions of saltwater, UV exposure, and physical wear and tear. Protective plastic coatings have become essential in preserving and enhancing the lifespan of various marine components.

Our comprehensive range of coating services is widely utilized in the marine industry. We cater to various applications such as:

ISP Coatings provides custom-formulated and expertly applied coating solutions for your marine and boating needs. We have designed our business and processes around the goal of helping you stay on track with accelerated production cycles and aggressive timelines—without sacrificing quality. We operate with turnaround times of 7-10 business days and sometimes quicker, depending on individual needs, workload, and other factors. With our comprehensive protective marine coating capabilities, we can serve as your go-to source for every project. Learn more about our nylon coatings, protective plastisol coatings, and chemical-resistant epoxy coatings below.

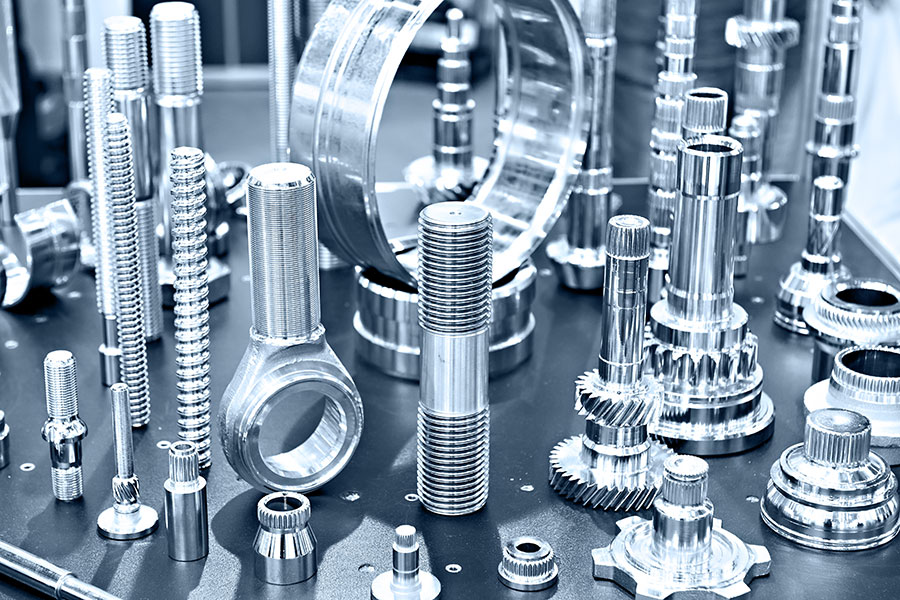

In the marine industry, nylon coatings offer unique benefits, particularly in components subjected to wear, impact, and extreme environmental conditions. Nylon is renowned for its exceptional strength, toughness, and resistance to abrasion, making it an excellent choice for applications such as components of propellers, impellers, and underwater equipment.

Nylon coatings provide protection against constant exposure to saltwater, marine organisms, and debris. They reduce friction, which enhances the performance and efficiency of moving parts while minimizing wear and extending the lifespan of marine components. The self-lubricating properties of nylon coatings reduce the need for additional lubricants, resulting in improved reliability and reduced maintenance costs.

Additionally, nylon coatings contribute to noise reduction in marine applications by dampening the vibrations caused by machinery, thereby enhancing the comfort and safety of passengers and crew members.

Plastisol coatings have gained significant popularity in the marine industry due to their outstanding protective qualities. Composed of PVC particles dispersed in a liquid plasticizer, plastisol offers exceptional resistance to corrosion, abrasion, and impacts.

One of the primary advantages of plastisol coatings is their ability to form a thick, flexible, and seamless layer that adheres well to various substrates. Marine equipment such as components and parts of boats and offshore structures benefit immensely from plastisol coatings, as they provide an effective shield against the damaging effects of saltwater, UV radiation, and physical forces. Additionally, plastisol coatings can be customized with different colors enhancing the aesthetics of marine components while maintaining their protective integrity.

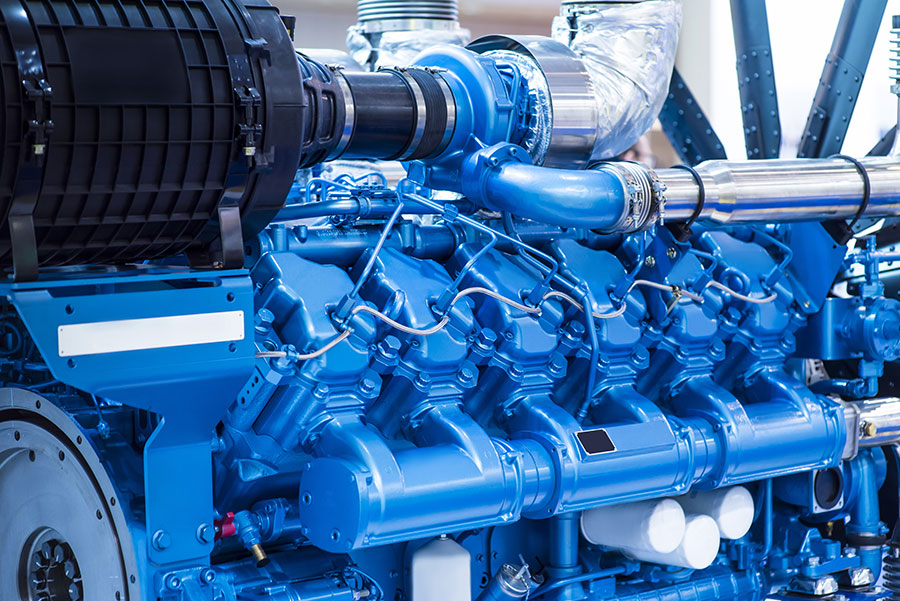

Epoxy coatings are widely recognized for their superior chemical resistance and exceptional durability. In the marine industry, where exposure to harsh substances like salt water, fuel, and chemicals is common, epoxy coatings play a crucial role in protecting metal surfaces, fiberglass, and concrete.

With their high build characteristics, epoxy coatings create a robust and impermeable barrier that prevents water intrusion and corrosion. These coatings excel in applications such as boating components and smaller parts. Epoxy coatings not only safeguard against corrosion but also provide excellent resistance to impact and abrasion, extending the lifespan of the components of marine structures and ensuring their structural integrity.

Selecting the appropriate protective plastic coating for marine applications depends on several factors, including the type of substrate, desired level of protection, aesthetic requirements, and budget considerations.

If you are looking for reliable and efficient coating solutions for your marine and boating needs, ISP Coatings is here to assist you. Get in touch with us today at 586-752-5020, and our knowledgeable team will be delighted to provide you with more information about our wide range of products and the specifics of our coating process.

Since its opening in 1975, ISP Coatings Corporation has built unsurpassed customer experiences and process excellence by lowering the total cost of ownership, while providing coating products ensuring improved product safety, performance, and durability.

Our Former Logo

© 2026 ISP Coatings Corporation

Website & SEO By: MI Digital Solution | Sitemap