Protective coatings play a significant role in stamping and machining industries by providing essential protection to various components and equipment used in manufacturing and metalworking processes. These coatings are applied to enhance durability, prevent corrosion, improve wear resistance, and increase the overall lifespan of the materials they are applied to.

ISP Coatings provides custom-formulated and expertly applied coating solutions for your machining and stamping needs. We have designed our business and processes around the goal of helping you stay on track with accelerated production cycles and aggressive timelines—without sacrificing quality. We operate with turnaround times of 7-10 business days and sometimes quicker, depending on individual needs, workload, and other factors. With our comprehensive protective machine and stamping coating capabilities, we can serve as your go-to source for every project. Learn more about our nylon coatings, protective plastisol coatings, and chemical-resistant epoxy coatings below.

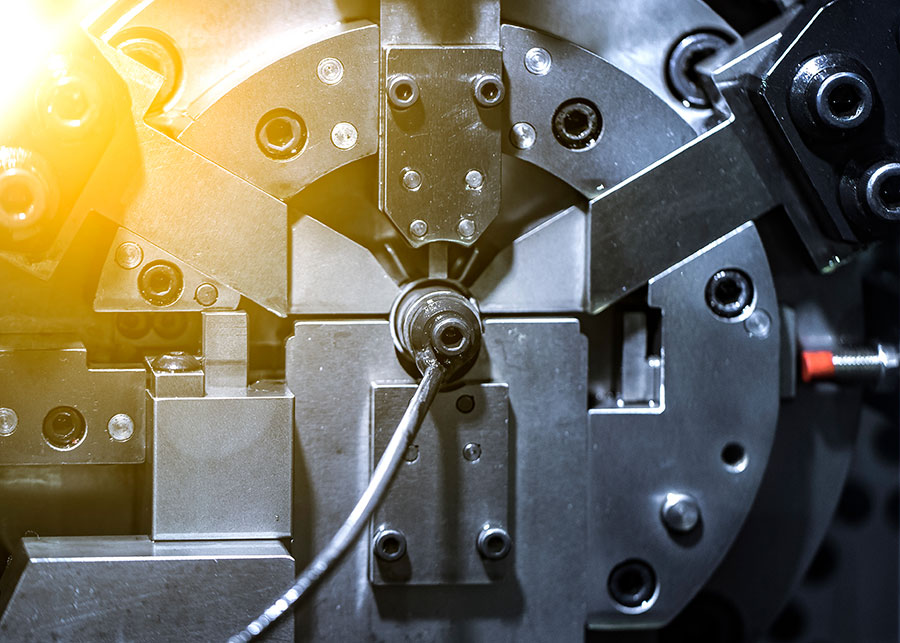

Nylon coatings find extensive usage in the stamping and machine shop industry due to their exceptional properties, including toughness, wear resistance, and high impact strength. When applied to tools, molds, and dies used in stamping operations, nylon coatings provide a barrier against scratches, abrasion, and friction.

One of the primary benefits of using nylon coatings is their resistance to chemicals and corrosion. This makes them ideal for applications where exposure to chemicals, coolants, solvents, and cutting fluids is common. Nylon coatings also offer good adhesion to metal substrates, ensuring a long-lasting protective layer that helps to extend the lifespan of tools and equipment.

Plastisol coatings, consisting of liquid polyvinyl chloride (PVC), have gained popularity in the stamping and machine shop industry due to their versatility and protective properties. These coatings are often used to provide a barrier against corrosion, improve grip, and enhance the aesthetics of components such as handles, grips, and knobs.

In stamping operations, plastisol coatings can be applied to press plates, metal stamping dies, and punches. They offer excellent impact resistance, reducing wear and minimizing damage caused by repeated contact with materials being stamped. Plastisol coatings provide a non-slip surface, improving grip and reducing the risk of accidents caused by slippage during handling.

ISP Coatings, a renowned manufacturer of coatings, offers a range of epoxy coatings specifically designed for the stamping and machine shop industry. These coatings offer exceptional chemical resistance, durability, and protection against wear and corrosion.

Epoxy coatings provided by ISP Coatings are widely used on machine parts, molds, and dies to prevent corrosion caused by exposure to chemicals, moisture, and abrasive substances. These coatings are also highly resistant to impact, minimizing damage from metal-to-metal contact and ensuring longevity in high-stress applications.

The chemical resistance of ISP Coatings’ epoxy coatings makes them suitable for use in environments where exposure to acids, solvents, lubricants, and cutting fluids is prevalent. This helps to protect sensitive components and preserve their functional properties.

When selecting a protective coating in the stamping and machine shop industry, it is crucial to consider the specific requirements of the application. Factors such as the material being coated, exposure to chemicals, temperature fluctuations, mechanical stress, and desired aesthetics all influence the choice of coating.

Nylon coatings excel in applications where wear resistance and chemical protection are critical, protecting tools and dies from abrasion and corrosion. Plastisol coatings are ideal for enhancing grip and providing a non-slip surface on handles and knobs. ISP Coatings’ epoxy coatings offer excellent chemical resistance and durability for machine parts subjected to corrosive environments and high mechanical stress.

If you are looking for reliable and efficient coating solutions for your machine shop or stamping needs, ISP Coatings is here to assist you. Get in touch with us today at 586-752-5020, and our knowledgeable team will be delighted to provide you with more information about our wide range of products and the specifics of our coating process.

Since its opening in 1975, ISP Coatings Corporation has built unsurpassed customer experiences and process excellence by lowering the total cost of ownership, while providing coating products ensuring improved product safety, performance, and durability.

Our Former Logo

© 2026 ISP Coatings Corporation

Website & SEO By: MI Digital Solution | Sitemap