Plastic protective coatings play a crucial role in the fitness industry, ensuring the durability, safety, and performance of small components and parts used in various exercise equipment. These coatings offer unique properties that are ideal for protecting small fitness equipment components against wear, corrosion, and other challenges.

ISP Coatings provides custom-formulated and expertly applied coating solutions for your fitness needs. We have designed our business and processes around the goal of helping you stay on track with accelerated production cycles and aggressive timelines—without sacrificing quality. We operate with turnaround times of 7-10 business days and sometimes quicker, depending on the individual needs, workload, and other factors. With our comprehensive protective fitness coating capabilities, we can serve as your go-to source for every project. Learn more about our nylon coatings, protective plastisol coatings, and chemical-resistant epoxy coatings below.

Nylon coatings are widely utilized in the fitness industry due to their exceptional strength, impact resistance, and anti-abrasive properties. These coatings provide a protective layer on small components, including pulleys, bearings, and sliders, ensuring their longevity and reliable performance.

The anti-abrasive nature of nylon coatings is particularly beneficial in the fitness industry, where components frequently undergo repetitive or heavy use. By minimizing wear and friction, nylon coatings help maintain the smooth operation and performance of fitness equipment.

Additionally, nylon coatings offer resistance against moisture and chemicals. Sweat and cleaning solutions commonly encountered in fitness facilities can cause damage and corrosion to small components. Nylon coatings prevent these corrosive agents from compromising the integrity of the coated parts.

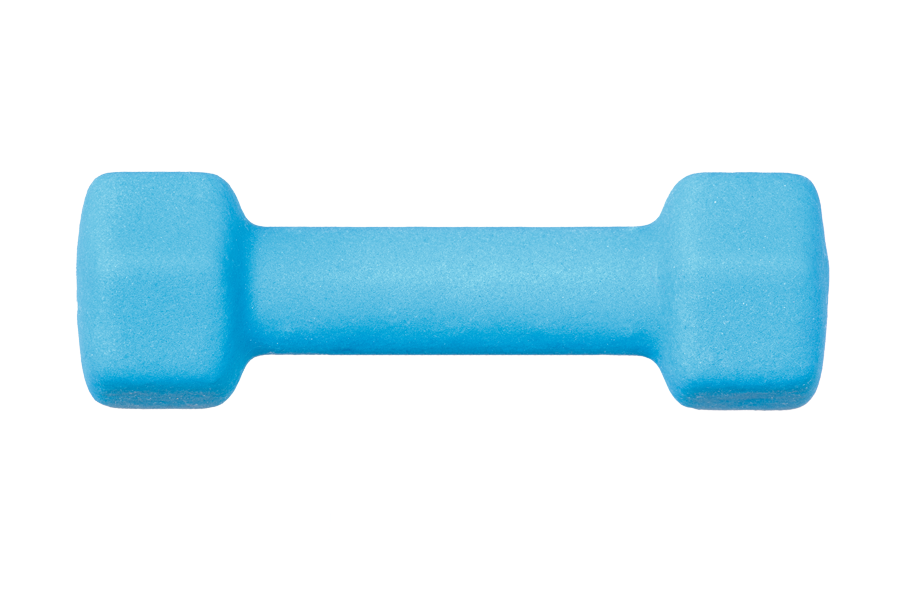

Plastisol coatings are extensively used in the fitness industry due to their excellent adhesion, impact resistance, and durability. These coatings are made from a suspension of PVC (polyvinyl chloride) particles in a liquid plasticizer, which forms a tough and resilient protective layer on the coated surfaces.

Fitness equipment components that come into contact with the user’s hands or body, such as handles, grips, and pads, often benefit from plastisol coatings. These coatings provide a comfortable and secure grip, reducing the risk of slippage and improving user safety.

Furthermore, plastisol coatings offer effective protection against corrosion and wear. Small metal parts, such as weight plates and dumbbell ends

Epoxy coatings, supplied by ISP Coatings, are known for their exceptional adhesion, chemical resistance, and durability. These coatings consist of a resin and hardener mixture that creates a strong and protective layer on coated surfaces.

Small electronic components used in fitness equipment, such as control panels and sensors, often benefit from epoxy coatings. These coatings provide an effective shield against moisture, dust, and other contaminants, ensuring the reliable performance and longevity of sensitive electronic parts.

Epoxy coatings also offer excellent chemical resistance, protecting coated components from potentially corrosive substances like cleaning agents or sweat. This resistance minimizes the risk of damage caused by chemical interactions, further enhancing the lifespan of fitness equipment parts.

Selecting the appropriate plastic protective coating for small fitness equipment components depends on factors such as the specific application, desired properties, and environmental conditions.

By utilizing the plastisol, nylon, and epoxy coatings produced by ISP Coatings, fitness equipment manufacturers and users can ensure the protection, performance, and longevity of small components and parts. Proper coating selection ensures that fitness equipment remains safe, reliable, and efficient, contributing positively to the fitness industry.

If you are looking for efficient coating solutions for your fitness and exercise equipment needs, ISP Coatings is here to assist you. Get in touch with us today at 586-752-5020, and our knowledgeable team will be delighted to provide you with more information about our wide range of products and the specifics of our coating process.

Since its opening in 1975, ISP Coatings Corporation has built unsurpassed customer experiences and process excellence by lowering the total cost of ownership, while providing coating products ensuring improved product safety, performance, and durability.

Our Former Logo

© 2026 ISP Coatings Corporation

Website & SEO By: MI Digital Solution | Sitemap