ISP Coatings Has Close To 5 Decades of Experience In The Coatings Industry! Our epoxy coatings offer excellent protection against several forms of corrosion and damage.

ISP Coatings is a well-known name in the field of industrial coatings. With close to five decades of experience, we have established ourselves as a reliable service provider for a range of coating requirements. One of the many services we provide is Epoxy Coatings.

Epoxy coating is a widely used industrial material that offers excellent protection against several forms of corrosion and damage. It is a thermosetting polymer that gives a durable and long-lasting finish. The epoxy coating is applied to metal substrates, which can be bare metal,

e-coat, zinc, phosphate, and oil amongst other materials. Once applied, it chemically bonds with the substrate to create a strong and durable surface that can withstand various environmental stressors.

Epoxy coatings by ISP Coatings Corporation can be useful for a wide range of surfaces and applications. You’ll commonly find this resilient coating in industries such as automotive parts, aviation and aerospace, marine, construction, and sporting goods. Its attributes make it an ideal material finding it to be eco-friendly, highly durable, and chemical and environment-resistant.

Here are some of the benefits you’ll see in our epoxy coating services:

Epoxy coatings have great longevity, lasting in challenging environments and able to withstand extreme temperatures, chemical exposure, water exposure, and abrasion.

Its stain resistance makes it incredibly simple to clean. This cuts maintenance costs, as you won’t need to repeatedly address smudges and stains.

Epoxy coatings can be applied to a diverse range of substrates, making it useful across both industrial and commercial domains.

Epoxy coatings come in a range of colors.

ISP Coatings Corporation offers a wide range of coating solutions for all kinds of industries. Our experts can find the solution that fits your needs.

We offer a more competitive piece price and shorter turn times on the products we produce. This in turn also allows us to meet our customers’ diverse shipping needs.

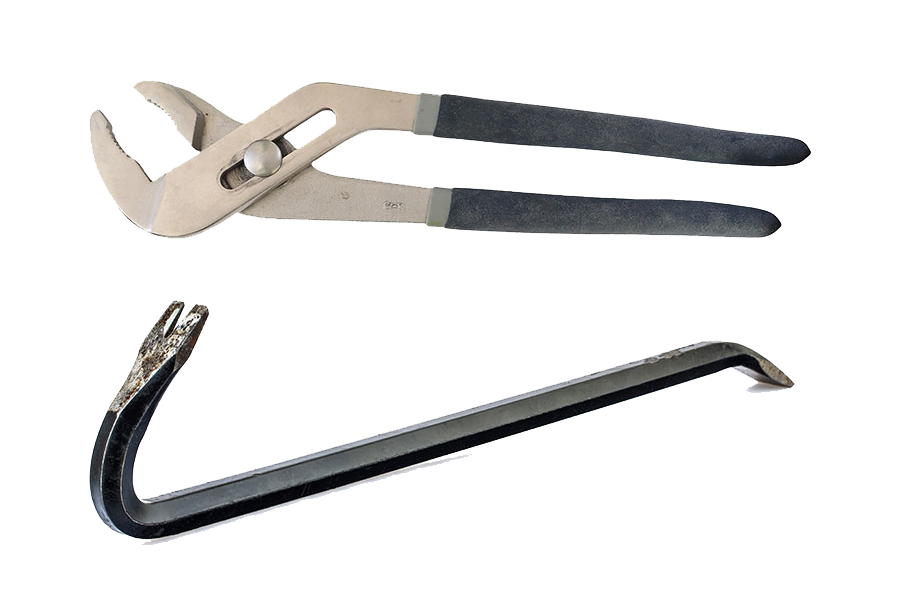

Hand Dipping Processes and components for:

ISP Coatings is your dependable service provider for epoxy coatings. Our expertise and experience in the field enable us to deliver solutions that meet the specific needs of our clients. The benefits of epoxy coatings, such as durability, ease of maintenance, and aesthetic appeal, make it a practical and cost-effective choice for various industrial and commercial applications. With ISP Coatings, businesses can rest assured that their epoxy coating requirements are in good hands.

Contact us today at (586) 752-5020 for a quote or you can also go to our online contact form.

Epoxy coatings offer several benefits for smaller components and parts. They provide excellent protection against corrosion and chemical damage, helping to extend the lifespan of the coated parts. Epoxy coatings also offer high adhesion, ensuring that the coating remains intact even under mechanical stress. Additionally, epoxy coatings can provide a smooth, attractive finish, enhancing the appearance of the smaller components.

Yes, epoxy protective coatings can be applied using the dip coating method. Dip coating involves immersing the object or part into a tank or container filled with the epoxy coating material. The object is then withdrawn at a controlled rate to allow excess coating to drain off and the remaining coating to cure and form a protective layer on the surface.

This method is commonly used for coating small to medium-sized parts, offering an efficient and uniform coating application. It is often employed in industries such as automotive, electronics, and manufacturing, where a protective layer is needed on various components.

Epoxy coatings can be formulated to be environmentally safe. It is important to choose epoxy coatings that are labeled as "green" or low in VOC (volatile organic compounds). These formulations minimize the release of harmful substances into the environment during application and usage.

Yes, epoxy coatings can be colored. Pigments or dyes can be added to the epoxy resin to achieve the desired color. This allows for customization and the ability to match specific aesthetic requirements or branding needs.

Since its opening in 1975, ISP Coatings Corporation has built unsurpassed customer experiences and process excellence by lowering the total cost of ownership, while providing coating products ensuring improved product safety, performance, and durability.

Our Former Logo

© 2026 ISP Coatings Corporation

Website & SEO By: MI Digital Solution | Sitemap