As an industry responsible for millions of drivers worldwide, the automotive sector places great emphasis on ensuring safety and durability. At ISP Coatings, we specialize in providing high-quality coating solutions for both OEM and aftermarket automotive parts and components.

We operate with turnaround times of 7-10 business days and sometimes quicker, depending on the individual needs, workload, and other factors.

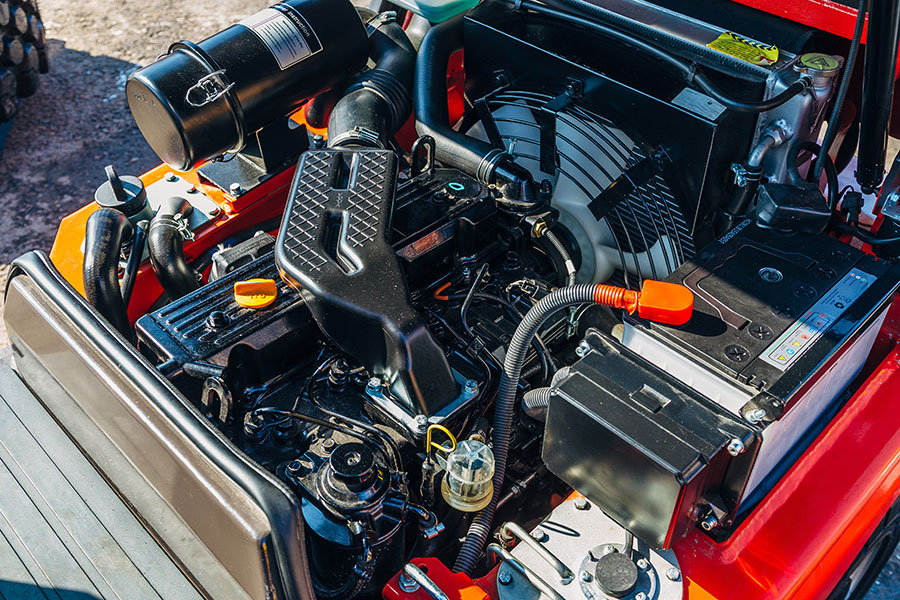

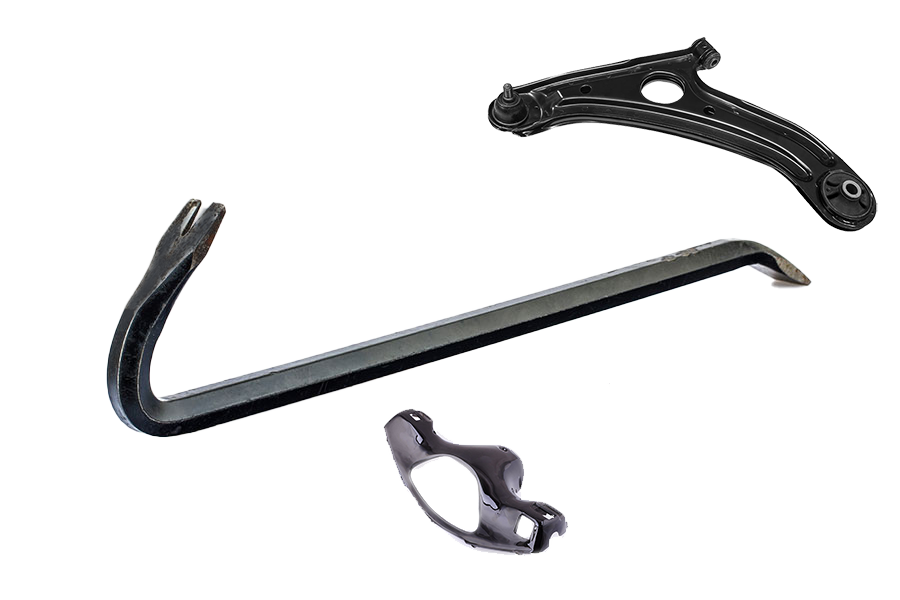

Our comprehensive range of coating services is widely utilized in the automotive industry. In addition to standard cars, we also coat parts for trucks, buses, motorcycles, and RVs. We cater to various applications such as:

ISP Coatings provides custom-formulated and expertly applied coating solutions for your automotive needs. We have designed our business and processes around the goal of helping you stay on track with accelerated production cycles and aggressive timelines—without sacrificing quality. We operate with turnaround times of 7-10 business days and sometimes quicker, depending on the individual needs, workload, and other factors. With our comprehensive protective automotive coating capabilities, we can serve as your go-to source for every project. Learn more about our nylon coatings, protective plastisol coatings, and chemical-resistant epoxy coatings below.

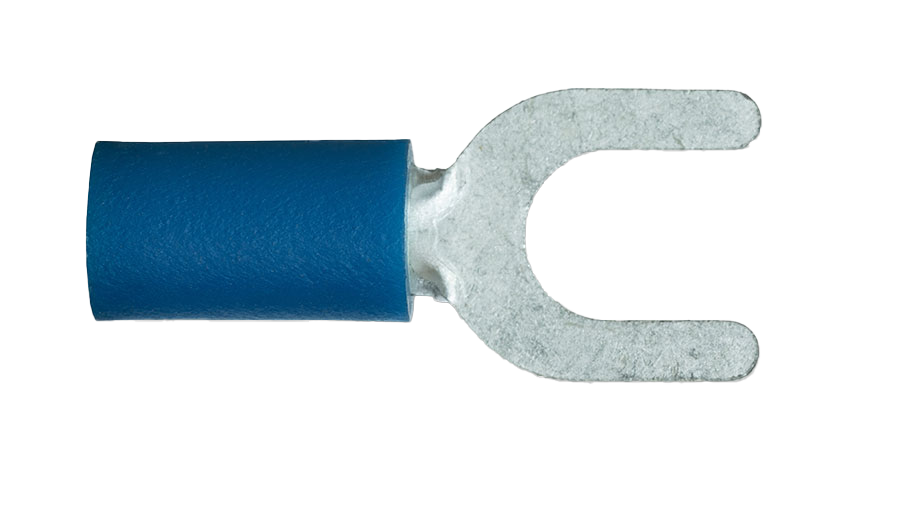

We offer a diverse selection of coatings to suit different automotive requirements, including plastisol, nylon, and epoxy. Each coating material offers specific properties that enhance the performance, durability, and aesthetic appeal of the coated parts.

To achieve superior coating results, we employ various application methods. Our capabilities include dip coating for thick film liquid vinyl PVC (plastisol), fluid bed powder coating for thick film powder coatings in various materials, and electrostatic spray powder coating for thin film powder coatings.

At ISP Coatings, we are dedicated to meeting and exceeding industry standards for safety and quality. We understand the critical importance of consistent and reliable coating solutions in the automotive sector. That’s why we continually strive to improve our processes and maintain the highest levels of compliance and customer satisfaction.

ISP Coatings Adhere to but is not limited to the following industry specifications:

Plastic coatings indeed offer various benefits to vehicle parts. They protect metal parts from oxidation, corrosion, and other damage caused by moisture, chemicals, and substances. Additionally, plastic coatings can reduce friction and wear, leading to improved durability and longevity for critical car parts like frames, axles, and gears.

Moreover, plastic coatings can enhance the comfort and safety of passengers. They can create more comfortable surfaces on controls, contribute to a quieter interior, provide insulation from electricity, and even improve vehicle performance. In terms of aesthetics, plastic coatings can also enhance the overall appearance of the vehicle.

If you have any specific questions or need further information about plastic coatings in the automotive industry, feel free to ask!

If you are looking for reliable and efficient coating solutions for your automotive needs, ISP Coatings is here to assist you. Get in touch with us today at 586-752-5020, and our knowledgeable team will be delighted to provide you with more information about our wide range of products and the specifics of our coating process.

Since its opening in 1975, ISP Coatings Corporation has built unsurpassed customer experiences and process excellence by lowering the total cost of ownership, while providing coating products ensuring improved product safety, performance, and durability.

Our Former Logo

© 2026 ISP Coatings Corporation

Website & SEO By: MI Digital Solution | Sitemap