Protective plastic coatings play a critical role in the aerospace industry, ensuring the longevity, performance, and safety of aircraft components and structures. These coatings offer unique properties that are essential in the demanding aerospace environment, providing protection against corrosion, wear, thermal stress, and other challenges.

The aerospace industry is undergoing a period of rapid expansion, and efficiency has become more critical than ever.

ISP Coatings provides custom-formulated and expertly applied coating solutions for your aerospace needs. We have designed our business and processes around the goal of helping you stay on track with accelerated production cycles and aggressive timelines—without sacrificing quality. We operate with turnaround times of 7-10 business days and sometimes quicker, depending on individual needs, workload, and other factors. With our comprehensive protective aerospace coating capabilities, we can serve as your go-to source for every project. Learn more about our nylon coatings, protective plastisol coatings, and chemical-resistant epoxy coatings below.

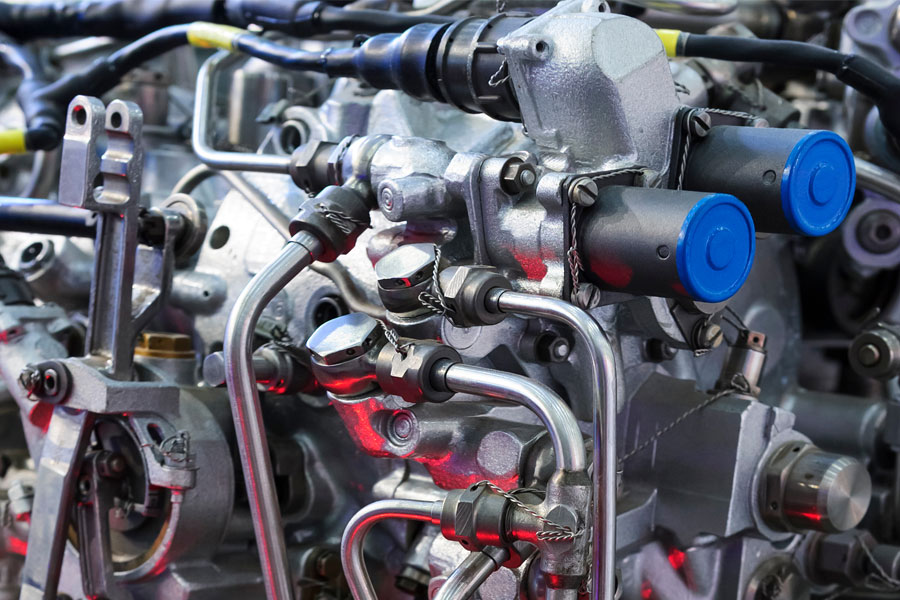

Nylon coatings are widely utilized in the aerospace industry due to their exceptional durability, resistance to impact, and anti-abrasion properties. These coatings provide a protective layer for various aerospace components, including engine parts, landing gear, and aircraft interiors.

The high chemical resistance of nylon coatings ensures protection against fuel, hydraulic fluids, and other corrosive substances typically found in aerospace environments. This resistance extends the lifespan of critical components and reduces maintenance requirements.

In addition, nylon coatings offer excellent thermal stability, making them suitable for applications where extreme temperature fluctuations occur.

Plastisol coatings are a versatile option widely used in the aerospace industry due to their ability to conform to complex shapes and provide excellent adhesion. These coatings, typically made from PVC (polyvinyl chloride), offer exceptional protection against corrosion, impact, and wear.

Aircraft components susceptible to corrosion, such as parts and components of fuel tanks and hydraulic systems, are often coated with plastisol to ensure their longevity and reliability. Plastisol coatings create a durable and impermeable barrier, preventing the penetration of moisture or corrosive agents.

Plastisol coatings also enhance the impact resistance of aerospace components. In areas prone to wear, these coatings act as a protective shield, reducing the risk of damage and maintaining structural integrity.

Epoxy coatings provided by ISP Coatings are widely used in aerospace applications for their exceptional adhesion, chemical resistance, and thermal stability. These coatings consist of a combination of resin and hardener, resulting in a robust and protective layer.

Aerospace components coated with epoxy benefit from increased resistance to corrosion, chemicals, and UV radiation. The chemically inert nature of epoxy coatings ensures reliable operation in various environments while minimizing the need for maintenance and repairs.

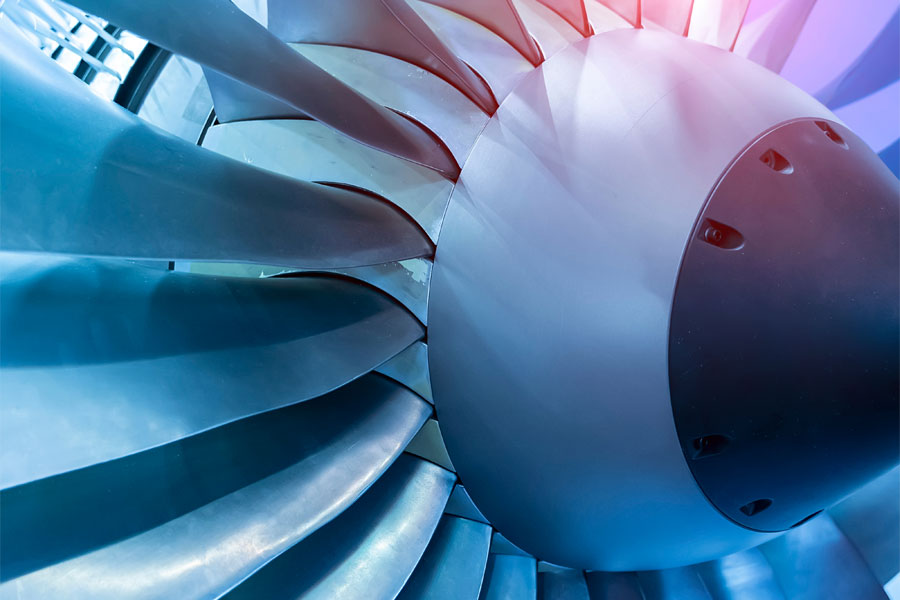

Epoxy coatings provide thermal stability, enabling aerospace structures to handle extreme temperature variations during flight. This capability is crucial as it prevents various forms of structural damage that could compromise the safety of the aircraft.

The selection of the appropriate protective plastic coating in the aerospace industry depends on several factors, including the specific application, desired properties, and environmental conditions.

ISP Coatings’ range of plastic coatings allows aerospace professionals to choose the coating that best suits their requirements. By selecting the appropriate coating, aerospace engineers can enhance the lifespan, performance, and safety of aircraft structures and components.

If you are looking for reliable and efficient coating solutions for your aerospace needs, ISP Coatings is here to assist you. Get in touch with us today at 586-752-5020, and our knowledgeable team will provide you with information about our products and coating process.

Since its opening in 1975, ISP Coatings Corporation has built unsurpassed customer experiences and process excellence by lowering the total cost of ownership, while providing coating products ensuring improved product safety, performance, and durability.

Our Former Logo

© 2025 ISP Coatings Corporation

Website & SEO By: MI Digital Solution | Sitemap